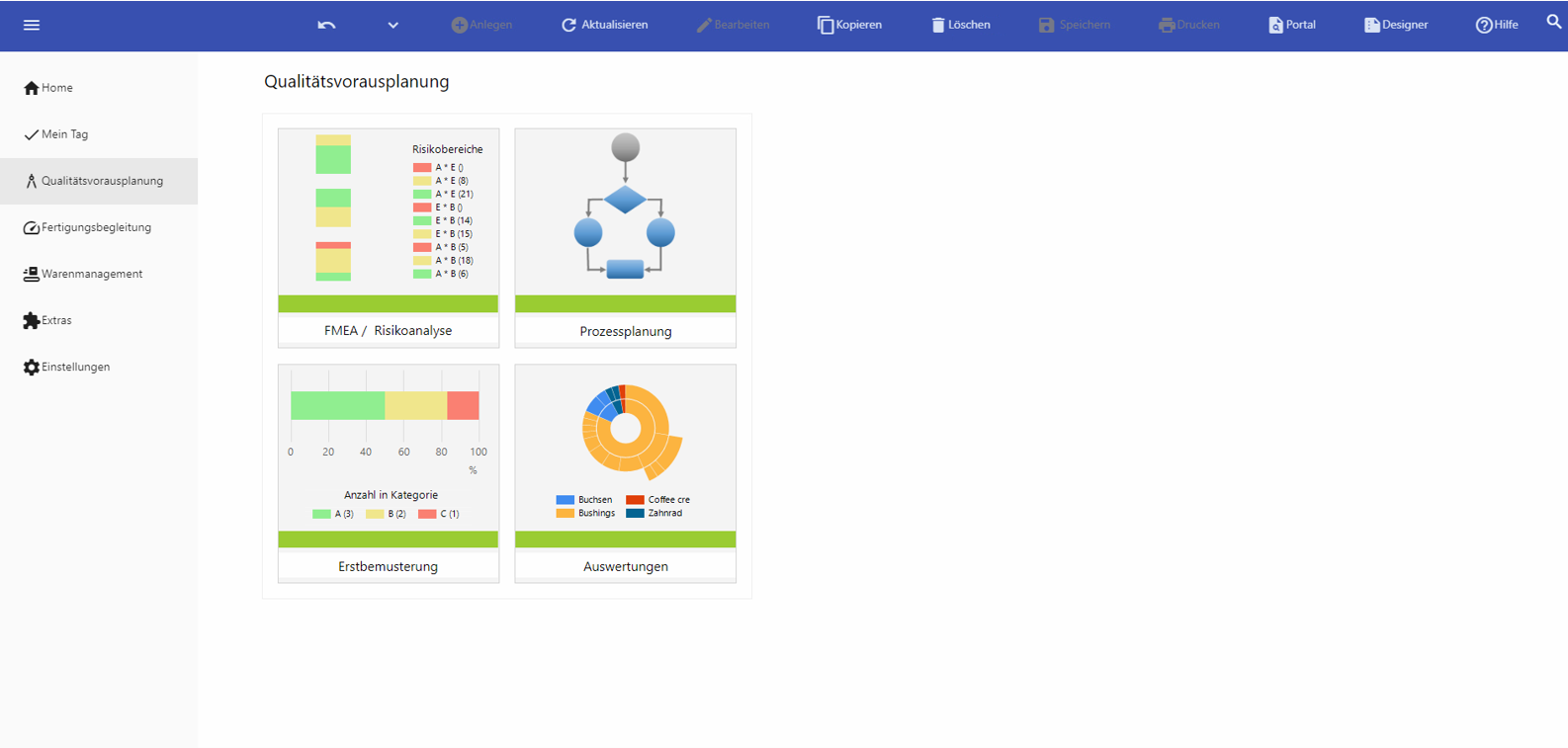

Define production based on APQP quality standards

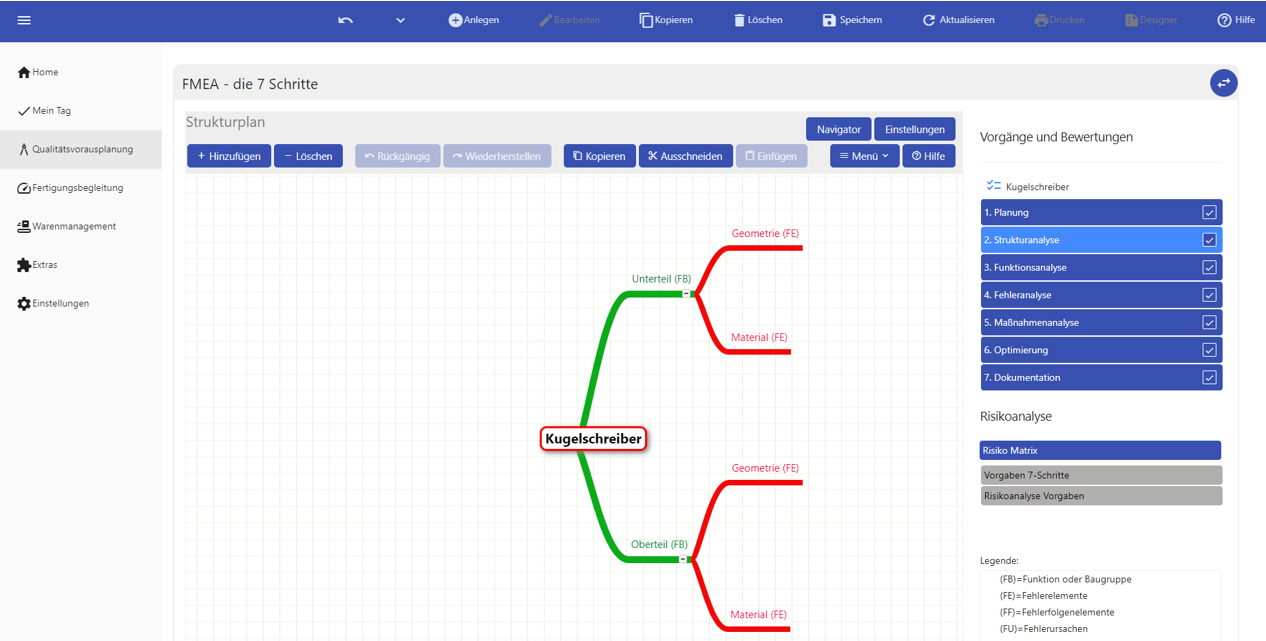

Harmonization VDA and AIAG:

The international standardization for a robust, accurate and complete FMEA

Key Features

-

Failure Mode & Effect Analysis (FMEA)

-

Graphical structural planner and functional analysis

-

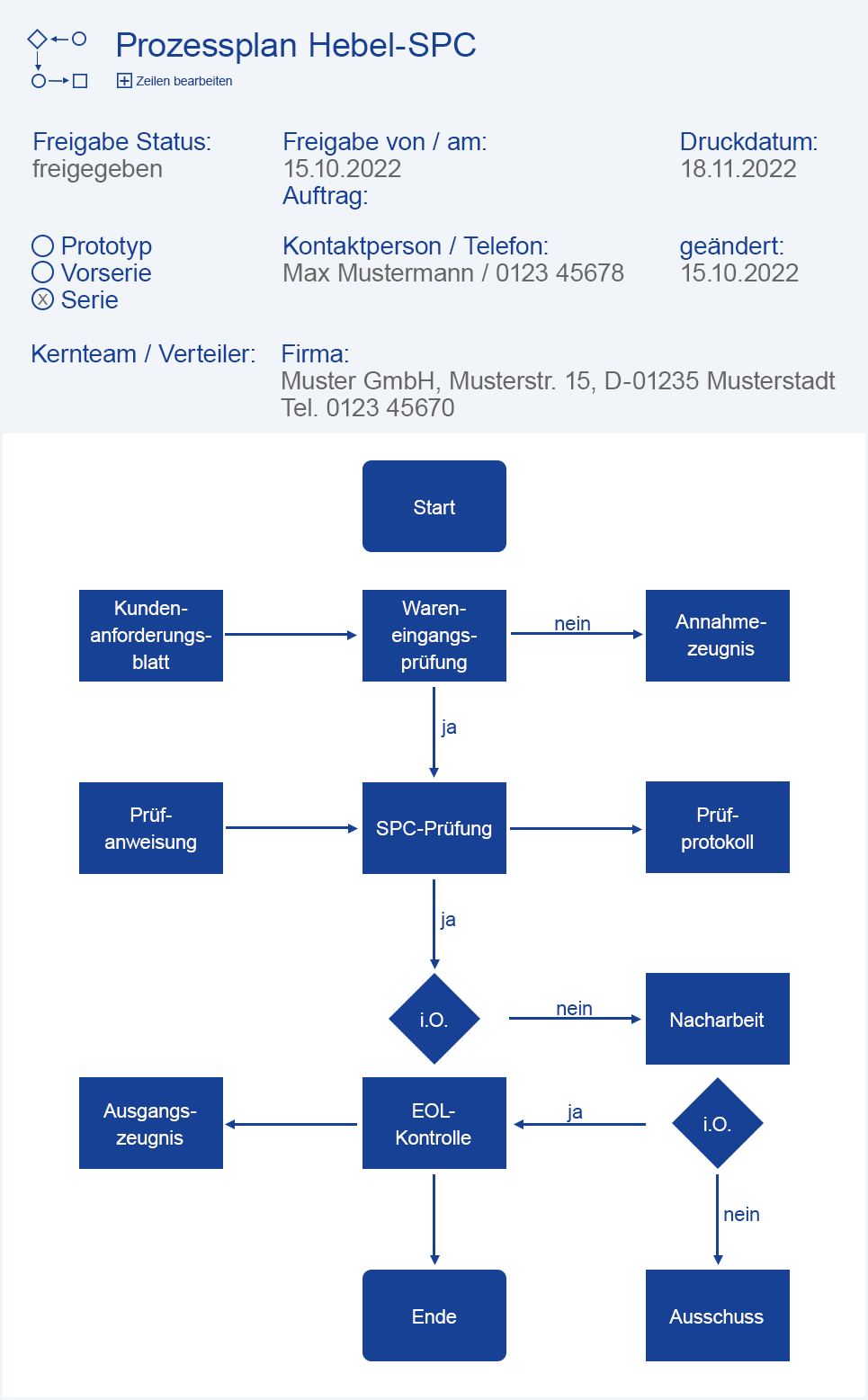

Browser based Process Flow Designer

-

Production schedules and inspection plans

-

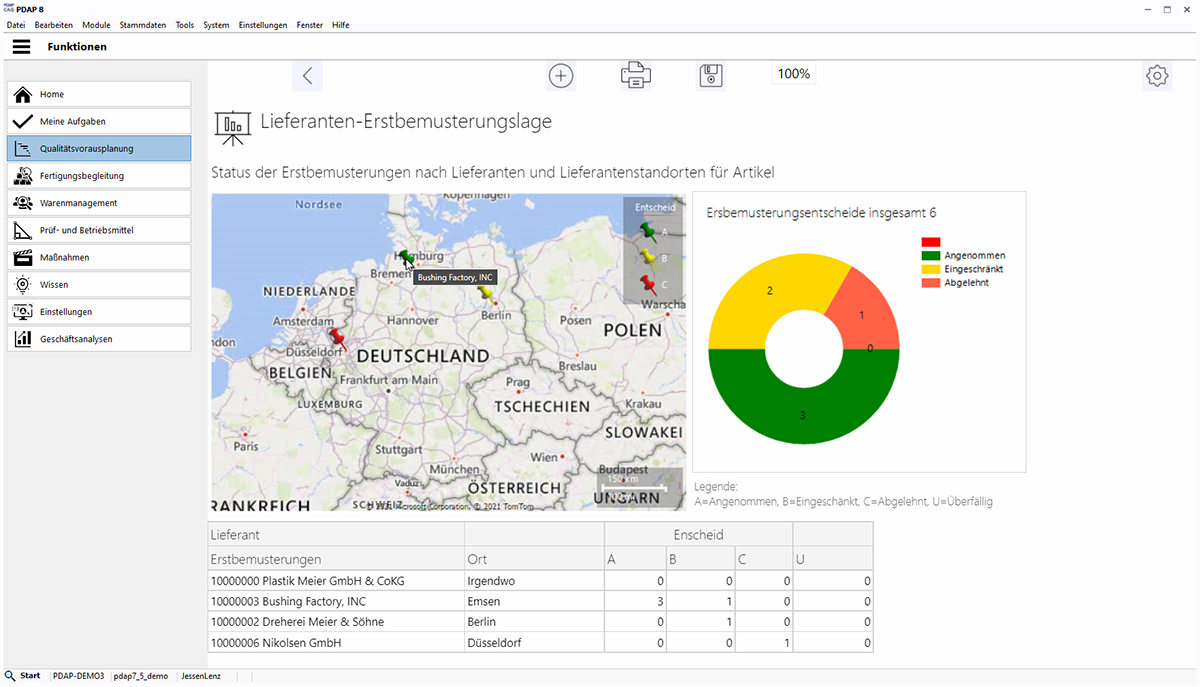

Initial sample inspection report

-

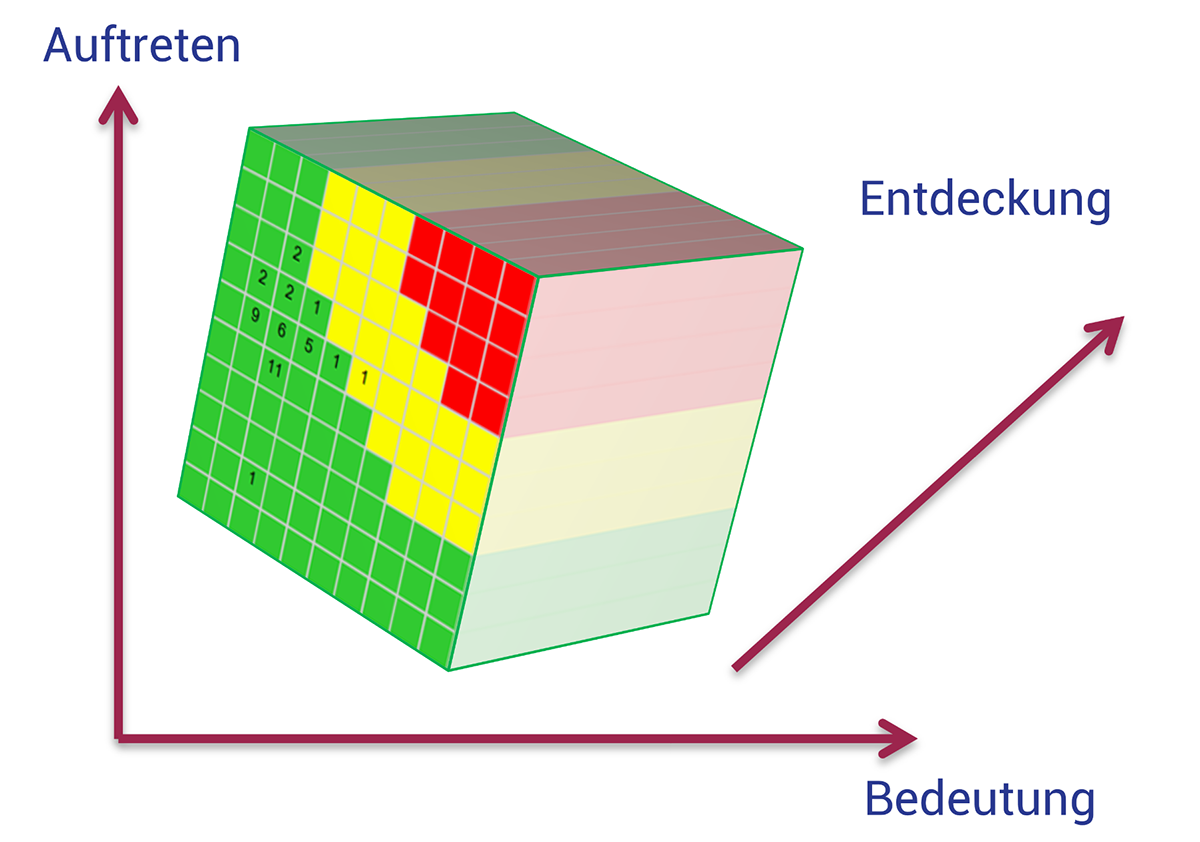

Risk matrix with traffic light factor

With APQP, you define the quality standards before the start of production. In PDAP 8, APQP forms an integrated chain in CAQ, accompanying the creation of the FMEA, the manufacturing support and inspection plans and with reference to warranty management.

With PDAP 8, the feedback of APQP, SPC as well as complaints in the CAQ system and the automatic generation of measures are organized. The linking of FMEA, inspection and process monitoring, the formation of new revisions as well as the process and cross-work information flow are of great advantage.

Important advantages

- Feedback APQP, SPC and REKL in the CAQ system

- System responses with reminders and automatic action generation

- Linkage when forming new revisions

- Time saving in data maintenance

- Information acquisition across processes and workflows

- Classic and integrated approach

- Linking FMEA, test and sequence planning with warranty

- Continuous analysis in the process support

- 8D linking of quality planning and aftermarket

Highlights

Assess processes and systems in risk areas