Verification system for capability and maintenance history

Test and resource management supports the planning, administration and monitoring of all relevant tasks.

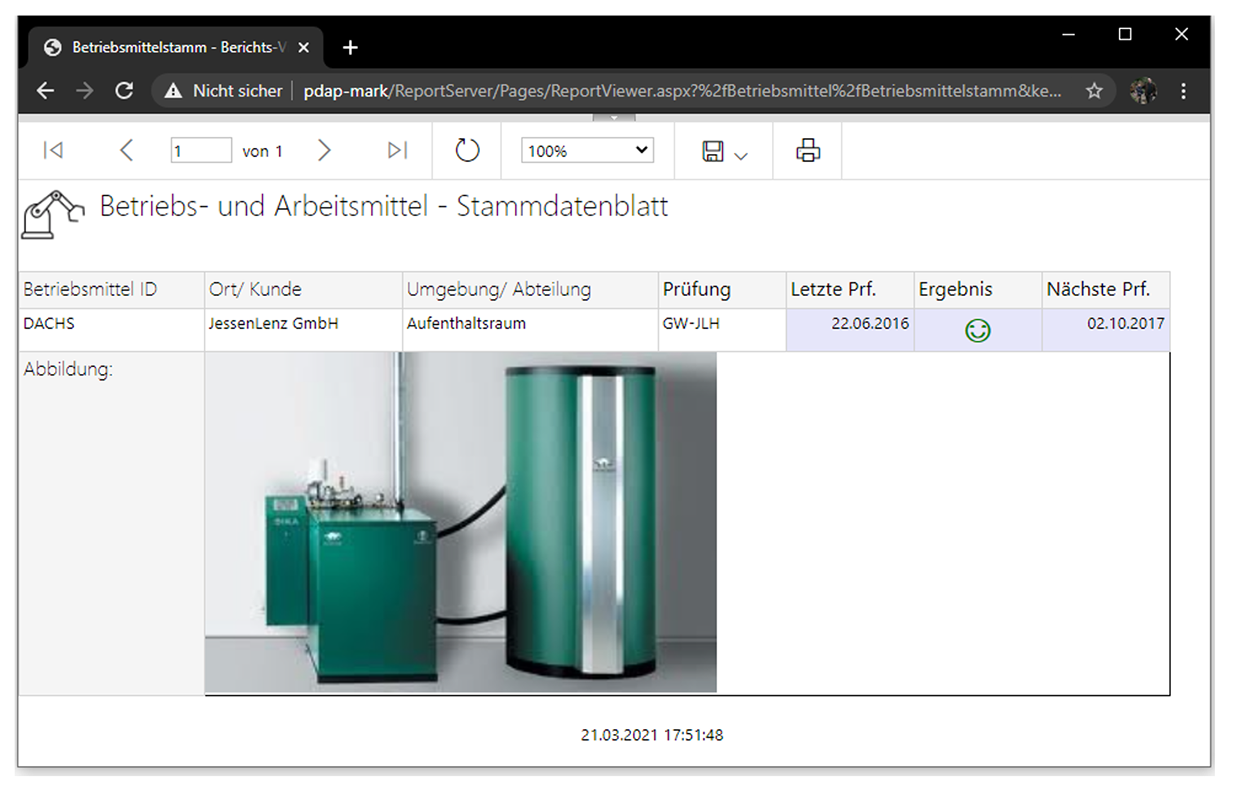

The management of test and operating equipment supports the planning, administration and monitoring of all relevant tasks. Independent monitoring cycles such as maintenance, service, calibration dates and calibrations can be defined for operating equipment, measuring and test equipment, tools and machines. The system monitors the issue and return of test and operating equipment. Furthermore, a reminder for automated reminders via e-mail and SMS when appointments are due. In addition, a system log, service report or factory calibration certificate is created and stored as a PDF document after service, testing, maintenance or calibration has been completed.

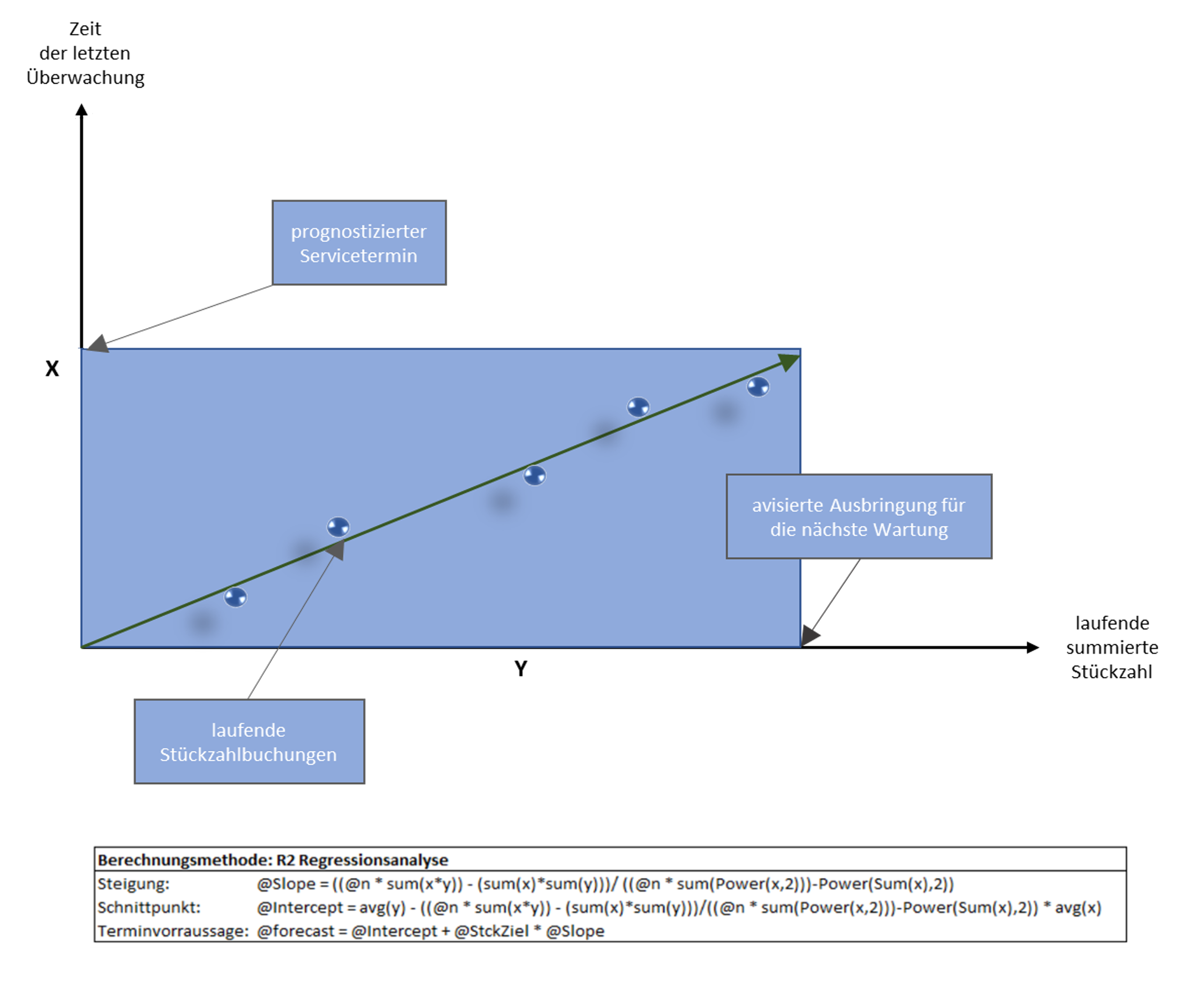

Likewise, monitoring by output quantities due to fluctuating volumes is possible. This means that the output quantities are regularly posted by the system and as soon as the specified quantity is reached, a monitoring date is generated.

Use the reminder service to have the inspector groups automatically informed about upcoming monitoring dates.

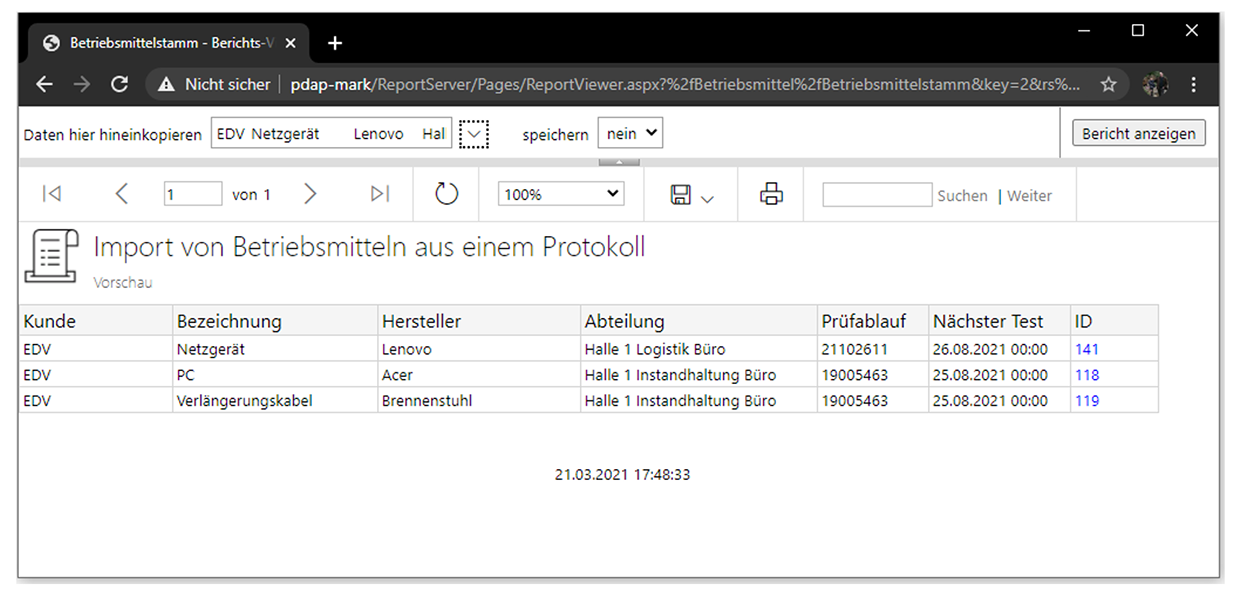

Use an import to connect logs for calibration and maintenance jobs that you place through external laboratories.

Use asset management to store external reports and logs on maintenance and monitoring for the maintenance order.

How do you ensure that the necessary logs have been attached to externally entered maintenance orders in all cases?

An automatic reminder service informs you, if necessary, about which performed maintenance forgot to attach important documents.

The CV audit for master data allows you to prove the change history on your test and operating equipment (IFS requirement).

Key Features

-

Test equipment life

-

Import of standards texts and test standards

-

Import of standard texts and test standardsCalculation of measurement tolerances and capabilities

-

Automatic blocking in case of missed deadlines

-

Own catalogs for manufacturers and suppliers

-

Planning, Controlling,Management

-

Cost recording

Important advantages

- Connection of test protocols from external laboratories

- Output and return postings with state history

- Connection to test and measurement equipment cabinet systems

- Plant management for test and maintenance orders

- Regular or forecast-based test intervals

- Maintenance intervals according to application rates with fluctuating volume

- Automatic reminder service

- Resume audit for master data changes

- Operating resource reports in the browser